At Rankin Steel & Rigging Pty Ltd, we offer top-notch hot dip galvanising services to protect your steel products from corrosion and enhance their durability. This process involves immersing steel in molten zinc, creating a robust protective coating that ensures resistance to corrosion and environmental damage.

At Rankin Steel & Rigging Pty Ltd, we offer top-notch hot dip galvanising services to protect your steel products from corrosion and enhance their durability. This process involves immersing steel in molten zinc, creating a robust protective coating that ensures resistance to corrosion and environmental damage.

What is Hot Dip Galvanising?

Hot dip galvanising is a method used to coat steel with a layer of zinc by immersing the metal in a bath of molten zinc. This process forms a metallurgical bond between the zinc and steel, offering excellent protection against rust and corrosion.

Benefits of Hot Dip Galvanising

- Corrosion Resistance: The zinc coating acts as a barrier, preventing corrosive substances from reaching the steel. This significantly extends the lifespan of the steel products, even in harsh environments.

- Durability: Hot dip galvanised steel can withstand extreme weather conditions, making it ideal for outdoor applications.

- Maintenance-Free: Galvanised steel requires little to no maintenance, reducing long-term costs and ensuring reliability.

- Cost-Effective: The initial cost of galvanising is lower than other protective coatings, and its long-lasting nature further adds to cost savings.

- Complete Coverage: The galvanising process ensures even coverage of all surfaces, including edges and corners, providing comprehensive protection.

Our Hot Dip Galvanising Process

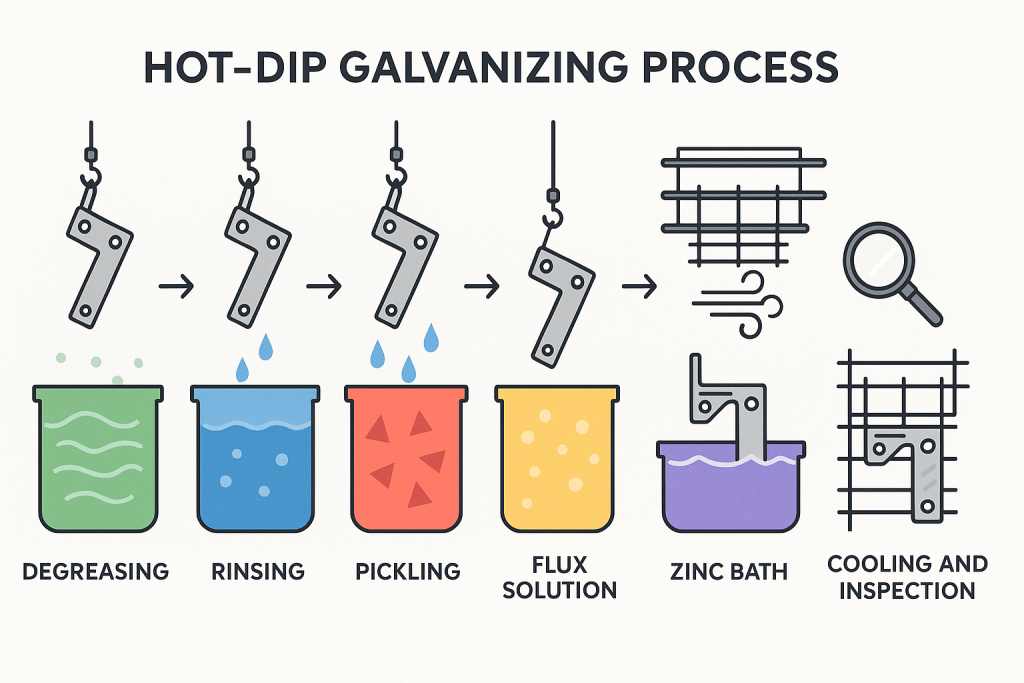

Every piece of metal that comes through our facility embarks on a journey of transformation. We’ve honed a meticulous six-step hot-dip galvanising process to ensure your metal components stand strong against corrosion for years to come. Here’s how we do it:

- Degreasing: We kick things off by stripping away oils and contaminants from the metal surface, leaving it spotless and ready for the next step.

- Rinsing: A thorough rinse follows, washing off any leftover cleaning solution to guarantee a pristine base.

- Pickling: Next, we tackle rust and scale with a pickling process that smooths out the metal, setting the stage for a flawless coating.

- Flux Solution: We then apply a flux solution—a critical prep step that protects the metal from oxidation and primes it for the zinc treatment.

- Zinc Bath: The magic happens here. The metal takes a dip in molten zinc, emerging with a tough, protective layer that’s built to last.

- Cooling and Inspection: Finally, we cool the metal and give it a detailed once-over, ensuring the coating meets our high standards.

This journey—from degreasing to inspection—isn’t just a process; it’s our commitment to quality. At Rankin Steel and Rigging, we take pride in turning raw metal into something durable and reliable, ready to tackle the elements.

Contact us for a quote today | 📞07 5537 9387 LET'S TALK

Applications of Galvanised Steel

- Construction: Used in structural beams, columns, and other building components to ensure longevity and structural integrity.

- Automotive: Commonly used in car bodies and chassis for rust prevention.

- Agriculture: Ideal for fencing, irrigation systems, and other outdoor equipment exposed to the elements.

- Utilities: Used in power transmission and telecommunications infrastructure to protect against environmental damage.

Why Choose Rankin Steel & Rigging Pty Ltd for Hot Dip Galvanising?

- Expertise: Our team has extensive experience in galvanising, ensuring high-quality results.

- State-of-the-Art Facilities: We use advanced equipment and technology to deliver superior galvanising services.

- Quality Assurance: Our rigorous quality control processes ensure that every product meets the highest standards of durability and corrosion resistance.

- Customer Satisfaction: We are committed to providing exceptional service and meeting the unique needs of our clients.

Areas We Serve

Rankin Steel & Rigging provides hot dip galvanising near you.

Across multiple areas in Queensland, including:

- Gold Coast

- Brisbane

- Northern Rivers

For more information or to discuss your hot dip galvanising needs, please contact Rankin Steel & Rigging Pty Ltd today.

Contact us

"*" indicates required fields

Frequently Asked Questions

What is hot dip galvanising?

Hot dip galvanising is the process of immersing steel in a bath of molten zinc to form a tough, metallurgical bond. This zinc layer acts as a barrier against moisture and contaminants, preventing rust and greatly extending the life of your steel products. It’s ideal for anything exposed to weather or corrosive environments.

Is hot dip galvanising better than cold galvanising?

Hot dip galvanising generally provides a thicker, more resilient coating than cold galvanising (which sprays or brushes on zinc). That extra thickness delivers superior corrosion resistance and a longer maintenance-free lifespan. Cold galvanising can be useful for touch-ups or small-scale repairs, but it won’t match the durability of a full hot dip treatment.

What is the difference between galvanised and hot dip galvanised?

“Galvanised” simply means coated with zinc, which can include various methods like electro-galvanising (thin, electrically applied layers). “Hot dip galvanised” specifically refers to immersion in molten zinc, producing a denser, more uniform coating. In short, all hot dip galvanised steel is galvanised, but not all galvanised steel is hot dip galvanised.

Is hot dip galvanising expensive?

While the upfront cost of hot dip galvanising may be higher than some surface coatings, it’s very cost-effective over the long term. The robust zinc layer means far less maintenance, repair or replacement down the track. For most applications, the lifetime savings on upkeep outweigh the initial galvanising charge.